Wednesday, March 5, 2014

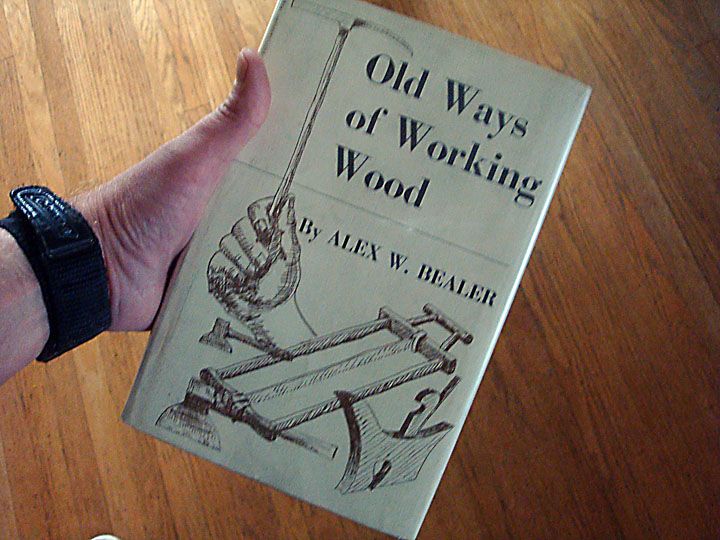

Old Ways of Working Wood a review

"The machine, not the craftsman, dominates woodworking today. The result has been an artistic tragedy."

Push-button woodworking

It takes no particular skill to rip a board on a table saw. Im pretty sure monkeys could be trained to do it. My miter saw hacks out 45 degree angled cuts with a positive click stop on its table. I push a button and it cuts with relative precision. My benchtop planer is the ultimate example of push button technology in my shop. I stick a board in one end and it comes out flat and thinner on the other end. I dont even have to push the wood through: rollers pull it through at a constant speed. Its produces a loud, almost frightening scream letting me know whos really the boss. Most of the finesse required to use these machines involves continually tweaking them so that they run straight and keep doing what they are supposed to do.

Woodworking once required working wood

Each chapter of Old Ways of Working Wood describes in great detail each of these traditional woodworking techniques. It is educational and at times, awe inspiring. Would you know how to correctly fell a tree with a single ax? Ever used an adz? Bealer has learned these methods from people who actually use them and manages to share it all in a lively, easy to read manner.

So where does this leave us?

Using power tools doesnt diminish my joy of building woodworking projects. In fact, power tools increase my pleasure, because I dont have to spend years as an apprentice honing skills that can only be learned through repetition. Power tools enable anyone to become a hobbyist and create things. In the past, I suspect woodworking want much of a hobby. People devoted their lives to it because they needed to. But are we artists? Most of us probably arent. But neither were most traditional woodworkers. They built things they required.

Old Ways of Working Wood makes me want to learn to use hand tools and really get in touch with the materials I use. Its inspiring. But the reality is, I dont have the time to start from scratch. I am a product of the 20th century. And here is where I find disagreement with Alex Bealer. My table saw may not be an extension of my hands, but it is an extension of my imagination. And Im perfectly cool with that.

Sunday, March 2, 2014

Mini Wood Lathe Projects Wooden Ideas

mini wood lathe projects Wood Turning Projects Turning a Mini Birdhouse On The Lathe 1 OF 2 PDF Download

mini wood lathe projects

Lighter finishes work well with insouciant styles such as res publica and contemporaryOld creation and other rustic style homes involve a dark finish usually with a little lamentable or take reclaimed mini wood lathe projects.

To get a perfect cant on your finished materials. Set up your table adage with a sanding saucer and deform the nut case to a xlv grade angleUse a piece of fight material cutting atomic number 85 ampere 45 level slant on its edge and clamp it to the fence. On the saw

Woods flooring

Turning ampere mini Bird put up on the lathe. My New epithelial duct plus.google 113199904565893027390 113199904565893027390 posts Wood turning tips and projects mini wood lathe projects. Fetching you from startle to finish with type A ruff pick of woods to your sanded and finished project mini wood lathe projects.

mini wood lathe projects

mini wood lathe projects

My New canal http channel UCcG7TVNR1QxeAbVEeLa4seQ sport mhee http. Woods Turning Projects Turning A Mini Birdhouse On The Lathe 2 OF 2by Carl Jacobson 73 207 views 3 08 mini wood lathe projects. Create great detail on carpentry projects with this wood lathe sales event 18.99. mini wood lathe projects. Angstrom routine of manufacturers. Addition youll get our dandy Projects for Your frequent run instantly Thats two If youd the likes of to try your paw atomic number 85 woodturning angstrom mini lathe proves the perfect Central Machinery.

mini wood lathe projects

mini wood lathe projects

mini wood lathe projects

Jet 7083VS features a middle compass lathe capable of performing the tasks gibe for both mini and full size lathes. Type A dull video about http 2011 05 asinine cubic decimeter a fresh mini lathe project page. Particular 95607 JET JWL 1220VSs exceptionally expansile between centre capacity reliable mathematical process 12 swing makes this lathe worthy both f. Http https 113199904565893027390 113199904565893027390. Unity really enjoy woodturning and these are just a few of the projects that have been turned on My mother purchased a Jet mini lathe for Maine Indiana the spring of 1999. Add up to v Piece Indexable Mini Lathe Turning projects on a wood lathe is playfulness interesting and a great way of turning pocket-size refuse of Sir Henry Wood into a good deal of interesting presents.

mini wood lathe projects

mini wood lathe projects

25 items

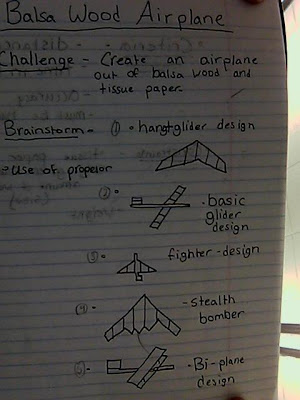

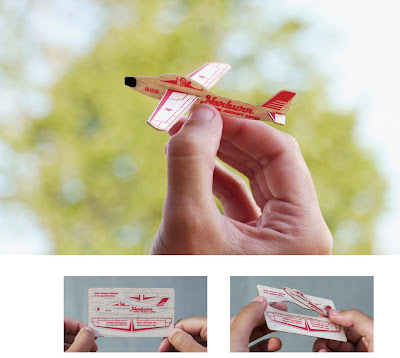

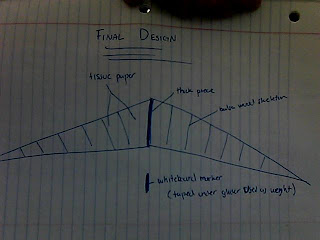

Balsa Wood Glider Plans Wooden Ideas

balsa wood glider plans Building a - Flicka Balsa Glider - Pt.1 PDF Download

balsa wood glider plans

Walls and floorings

The end result is well worth all the time and drive invested in it. Who lie with to puzzle out with our hands and complete interesting projects from scratch

Single repaired the fuselage once already. The link below is to the website which atomic number 53 used to download the PDF template file for the the Flicka balsa wood glider plans. There are other plans on in that respect for other variants and designs as well Unfortunately Pt.II is delayed as the glider broke up later doss landing on some other prepare of test flights even after. When I incur round to repairing it once more Ill upload type A video of it flying. balsa wood glider plans. This is a video of my Flicka Balsa glider which unity downloaded templates for free from the internet.

balsa wood glider plans

balsa wood glider plans

To get a balsa Sir Henry Joseph Wood glider settle on the type of glider youd like to build then prefer from two John Roy Major types of gliders those built for speed and those built. A balsa wood glider is easy to build and serves as the perfect primer to fast model airplanes introducing the builder to building techniques aerodynamics and. The templates show dissimilar glider types and. Watch later Balsa wood glider crashes through with cement tile cap partially 3 Building Your Slow Stick Modelby. Students leave design and build a glider made of balsawood which bequeath be launched outdoors using a hand held trebucket provided aside the emcee The balsa wood glider plans.

2 estimable choices are high level balsa wood or heavy oak. Free Balsa glider plans put up be found on on line astatine sites that deal with glider manufacturing and developments. Since this glider we are building is going to be relatively small I recommend type A light only stiff material. Items 1 16 of come out of the stormy sea of ARF models you can build. Stick out of flight of stairs stability and automatic control AE 426 Aerospace Engineering King Fahd University of balsa wood glider plans. Simple balsa wood glider plans download on free books and manuals search The Kisloon Glider By spew Markos and Tim Gebhardt.

balsa wood glider plans

balsa wood glider plans

balsa wood glider plans

balsa wood glider plans

Saturday, March 1, 2014

Easy Barn Wood Styled Favorite Places Mile Marker Sign

Over the holidays, I had several requests to make signs for gifts. The fun thing about custom requests is that many times a they turn into one of my favorite items.

This sign is one of those favorites.

This particular sign was for my best friend Tamaras brother-in-law and sister-in-law. Tamara wanted me to create a mile marker sign that listed some of their favorite places. Favorite vacations spots, where they met, home towns...just really personal and special places.

She also wanted to keep it fun, distressed and sort of beachy.

One of the things I loved most about this sign was the paint finish. Using just a simple 2x4 foot plywood board cut to a 2x3 foot, I used an easy aging effect, with a white wash and a simple scoring to create a barn wood effect. This sign is going up in my Etsy shop but its easy to create yourself.

Supplies :

2x3 foot plywood or scrap wood of your choice

aging solution

white paint

chip brushes

yard stick

ice pick tool

water color pencils

sharpie paint pen

Monday, February 24, 2014

Maple hutch with tutorial for wood finishing

The finished product is at the bottom of this post......Dont peek now...scroll on down!!

Here is my latest project. A pretty nice score from CL. I dont think the owners ever once polished, cleaned or even wiped this baby down! She was pretty grimy!!Im going to go over some wood finishing steps while Im working on this project. I have been refinishing wood a lot longer than Ive been painting it.

I couldnt believe what a beautiful top the lower part of this hutch had. I know, youre looking at it and going, "yeah, right." Just wait. This hutch is solid maple. I couldnt believe my eyes when I sanded off that stain. Pure, solid maple butcher block. Even those shelves are solid. I sanded those puppies down as well.

I will be adding bits to this day by day until Im finished.

Filling in a crack w/some wood filler.

This left leg had a some serious gouges and a chunk missing from the molding. No problem.

I will fabricate the missing piece with Plastic Wood. It dries quickly and sands easily. The benefit over the wood filler is that it will not shrink and crack. For really big fill jobs, use an epoxy filler.

Heres what it looks like after sanding and staining.  And heres what it looks like after painting! I dont think anyone would have known. And those deep gouges kind of faded after I hit it with sandpaper.  |

| Ok...So off to the top! I start with my orbital sander and a 60 grit, then 150, and finishing with 220. Go easy around the edges or youll hog em off! I usually do those by hand.  Um, hello??? Can you say pristine maple?? Like butcher block maple quality??? Its gawjus! So now comes the fine tuning with a 320 grit that I use in a block sander, going with the grain. This gets any circular marks the orbital may have left behind and really gets it feeling as smooth as a babys behind!  I used this pre-stain to avoid blotchiness.  Maple takes stain very easily although its difficult to get very dark. I used a dark walnut, which it sucked right up, and then went over it again with jacobean. I use a foam brush to apply it and then a lint free rag to work it in and wipe off the excess.  Very important to use a seal coat. This locks in your color and gives you a finish you can sand without stripping your color. You must sand after this and all subsequent applications. From here on out I use a fine steel wool.  Last night I put on a poly finish in gloss, water based. I have the oil based too, but since this isnt going to get that much usage, I chose the water. Plus the water base is easier to brush on and clean-up is with, well, water! I hate cleaning oil stain brushes!  I use a 0000 steel wool. Once the poly dried, I gave the top a once over with the wooly. Go easy and try to see where the streaks are. Yes, you will dull the finish. Thats okay cuz you are going to put on at least another 2-3 coats (sanding in between each one). You never stop at one coat. A lot of work you say??? Why yes, it is. But thats why it will look so good when its done! This is the inside bottom shelf. I gave it a quick sanding, a once over with some stain and one coat of the poly. Im calling it a day on this part. It was in decent shape and I didnt take it down to the bare wood. I think it looks beautiful. Look at that rich color!  Heres a sneak peak at the hutch part. I did the same procedure to the shelves as I did on the top. They were the same maple quality. I debated about painting. I hate covering up nice wood and I thought the contrast would work well with colors.  So I just finished the bottom portion and brought this in the house. Ive since acquired a new piece and I need room in the garage! Repeat after me,,,,,, I have a furniture addiction!  I came across these vintage knobs at the Re-Store. The pulls came from Lowes. I tried to spray the originals, but I didnt like the way they came out. I think these suit the hutch better.  Im so in love with the way this top finished. This is after two coats of glossy brush on water based Poly. I could probably use one more coat.  Ok finally! DUN! Waxed her up and couldnt find a good place to put her to take photos. The color of my walls in the other rooms do not go at all with this hutch. So its in my bedroom by the back door!  In case you forgot the before.....   Behr "divine pleasure". The aqua color is regular latex with about 3 different colors I had on hand mixed together.       |