Showing posts with label of. Show all posts

Showing posts with label of. Show all posts

Wednesday, March 5, 2014

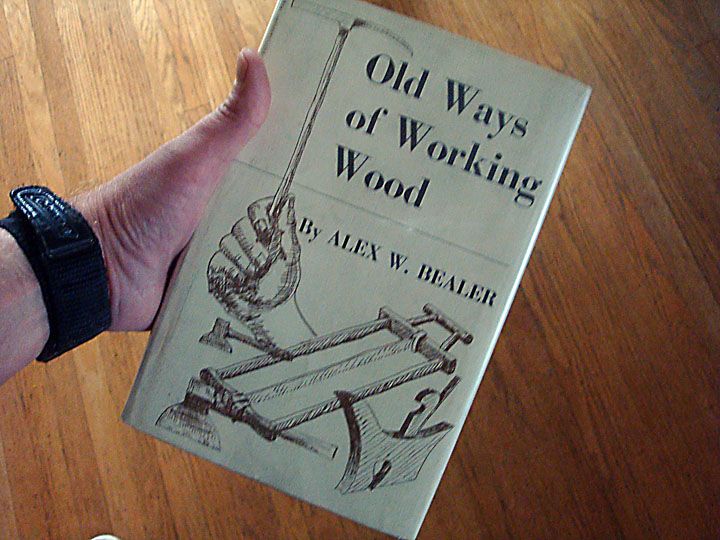

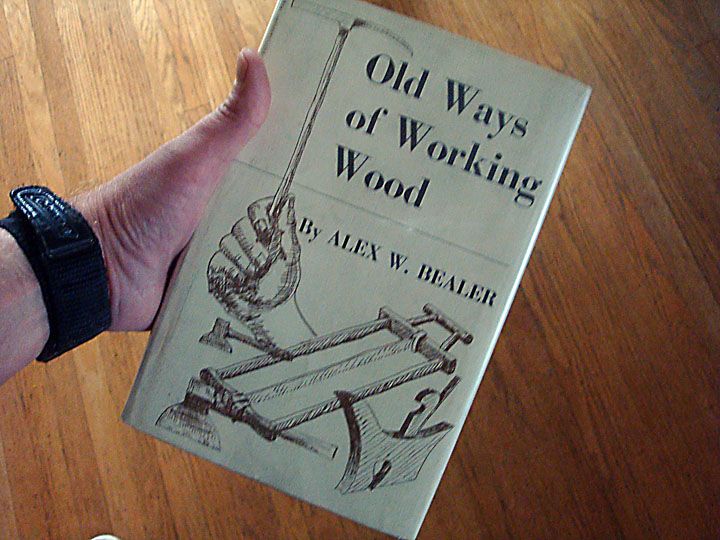

Old Ways of Working Wood a review

Id like to recommend a fascinating book I picked up at the library last week: Old Ways of Working Wood by Alex W. Bealer. The author clearly states his position on modern woodworking in the opening chapter:

by Alex W. Bealer. The author clearly states his position on modern woodworking in the opening chapter:

Those are some pretty strong statements. Are we, as power tool enthusiasts fooling ourselves into believing that we are actually creative, let alone artistic? Are we merely button pushers and no longer craftsmen? Sadly, as a confirmed power tool user, I agree with Bealer — to a point.

Those are some pretty strong statements. Are we, as power tool enthusiasts fooling ourselves into believing that we are actually creative, let alone artistic? Are we merely button pushers and no longer craftsmen? Sadly, as a confirmed power tool user, I agree with Bealer — to a point.

Push-button woodworking

It takes no particular skill to rip a board on a table saw. Im pretty sure monkeys could be trained to do it. My miter saw hacks out 45 degree angled cuts with a positive click stop on its table. I push a button and it cuts with relative precision. My benchtop planer is the ultimate example of push button technology in my shop. I stick a board in one end and it comes out flat and thinner on the other end. I dont even have to push the wood through: rollers pull it through at a constant speed. Its produces a loud, almost frightening scream letting me know whos really the boss. Most of the finesse required to use these machines involves continually tweaking them so that they run straight and keep doing what they are supposed to do.

In todays shop, we solve woodworking problems by making jigs and figuring out countless ways to best exploit the machine. In a sense, we are slaves to the capabilities and limitations of our machines. Moreover, if a certain power tool doesnt provide the results we desire, we go shopping for a bigger or better machine that will. If we want to create a certain router profile, we buy a pre-made bit that will suffice. Or settle for one thats close enough to what we envision. Want to make mortises? There are machines that bore perfectly square holes. At what point are we no longer working the wood, and just cutting out dough with cookie cutters?

In todays shop, we solve woodworking problems by making jigs and figuring out countless ways to best exploit the machine. In a sense, we are slaves to the capabilities and limitations of our machines. Moreover, if a certain power tool doesnt provide the results we desire, we go shopping for a bigger or better machine that will. If we want to create a certain router profile, we buy a pre-made bit that will suffice. Or settle for one thats close enough to what we envision. Want to make mortises? There are machines that bore perfectly square holes. At what point are we no longer working the wood, and just cutting out dough with cookie cutters?

Woodworking once required working wood

Bealer points out that all of this has, for the most part, come about within the past hundred years or so. Before the 20th century, a man literally worked wood, starting with the tree itself. He understood the growth of trees and had knowledge of the ones surrounding him. Building with wood began by felling the tree. From there the woodworker would hew and split the wood. Saw it, plane, bore it, chisel it, turn it, and cut joints. A craftsmans imagination wasnt limited to the tools he had on hand or could buy. If he needed, say, a specialized plane for something he dreamed up, he made his own. Woodworkers viewed their tools as highly personal objects and saw them as extensions of their own hands. Each project was unique because the craftsman was intimately involved with the wood.

Bealer points out that all of this has, for the most part, come about within the past hundred years or so. Before the 20th century, a man literally worked wood, starting with the tree itself. He understood the growth of trees and had knowledge of the ones surrounding him. Building with wood began by felling the tree. From there the woodworker would hew and split the wood. Saw it, plane, bore it, chisel it, turn it, and cut joints. A craftsmans imagination wasnt limited to the tools he had on hand or could buy. If he needed, say, a specialized plane for something he dreamed up, he made his own. Woodworkers viewed their tools as highly personal objects and saw them as extensions of their own hands. Each project was unique because the craftsman was intimately involved with the wood.

Each chapter of Old Ways of Working Wood describes in great detail each of these traditional woodworking techniques. It is educational and at times, awe inspiring. Would you know how to correctly fell a tree with a single ax? Ever used an adz? Bealer has learned these methods from people who actually use them and manages to share it all in a lively, easy to read manner.

So where does this leave us?

Using power tools doesnt diminish my joy of building woodworking projects. In fact, power tools increase my pleasure, because I dont have to spend years as an apprentice honing skills that can only be learned through repetition. Power tools enable anyone to become a hobbyist and create things. In the past, I suspect woodworking want much of a hobby. People devoted their lives to it because they needed to. But are we artists? Most of us probably arent. But neither were most traditional woodworkers. They built things they required.

Old Ways of Working Wood makes me want to learn to use hand tools and really get in touch with the materials I use. Its inspiring. But the reality is, I dont have the time to start from scratch. I am a product of the 20th century. And here is where I find disagreement with Alex Bealer. My table saw may not be an extension of my hands, but it is an extension of my imagination. And Im perfectly cool with that.

Read More..

"The machine, not the craftsman, dominates woodworking today. The result has been an artistic tragedy."

Push-button woodworking

It takes no particular skill to rip a board on a table saw. Im pretty sure monkeys could be trained to do it. My miter saw hacks out 45 degree angled cuts with a positive click stop on its table. I push a button and it cuts with relative precision. My benchtop planer is the ultimate example of push button technology in my shop. I stick a board in one end and it comes out flat and thinner on the other end. I dont even have to push the wood through: rollers pull it through at a constant speed. Its produces a loud, almost frightening scream letting me know whos really the boss. Most of the finesse required to use these machines involves continually tweaking them so that they run straight and keep doing what they are supposed to do.

Woodworking once required working wood

Each chapter of Old Ways of Working Wood describes in great detail each of these traditional woodworking techniques. It is educational and at times, awe inspiring. Would you know how to correctly fell a tree with a single ax? Ever used an adz? Bealer has learned these methods from people who actually use them and manages to share it all in a lively, easy to read manner.

So where does this leave us?

Using power tools doesnt diminish my joy of building woodworking projects. In fact, power tools increase my pleasure, because I dont have to spend years as an apprentice honing skills that can only be learned through repetition. Power tools enable anyone to become a hobbyist and create things. In the past, I suspect woodworking want much of a hobby. People devoted their lives to it because they needed to. But are we artists? Most of us probably arent. But neither were most traditional woodworkers. They built things they required.

Old Ways of Working Wood makes me want to learn to use hand tools and really get in touch with the materials I use. Its inspiring. But the reality is, I dont have the time to start from scratch. I am a product of the 20th century. And here is where I find disagreement with Alex Bealer. My table saw may not be an extension of my hands, but it is an extension of my imagination. And Im perfectly cool with that.

Monday, March 3, 2014

Lack of Motivation

Another post ...at last!... Sadly again without in any real useful or interesting content.

Lately (as regular readers can probably tell), I have been lacking motivation in the wood working department - for a number of reasons.

Firstly, I dont have any wood around thats suitable for any of the things Id actually like to make - such as a tool chest. My Timber Investment is still drying out in the shed and wont really be ready for anything other than really rustic work and gardening projects for a little while and I am too tight to purchase more premium cost wood from the timber yard.

Secondly, in my quest to escape the timber merchant, I have been trying to process the raw billets of Oak and Walnut with a lot of frustration! While my little bench was fine for pre planed wood, its simply not man enough to handle the rough scrubbing of the billets down to usable dimensions. The poor thing racked so violently, it almost fell to pieces!

The base twisted so badly that the bottom shelf fell out and I swear the bench tried to escape from me by smashing through its supporting wall! Anyway, ... I will try and brace the bench up and bite the bullet and make it as low as possible to see if that helps with planing, while I try and ignore the obvious - Make a PROPER BENCH!

And I thought everybody was building Roubo benches just because they were just fashionable!

Lastly, being as OCD as I am, I find it really hard to obsess about more than a single topic of interest at any one time and lately that topic of interest has been gardening. The gardening obsession was born through my overall interest in Self Sufficiency, which in turn has led me back to wood working, albeit of a slightly different nature this time. As I have cut down a few small trees in the garden lately, I find myself staring at their small trunks and wondering if theres any usable wood inside...

I found a guy selling really cheap (less than £30 inc P&P) Froes on Ebay. Its not hand forged or anything fancy but its certainly good at its job. I really wish Id had this tool while in France playing with the Oak and Walnut logs. I carved a mallet for it from one of the small trees, to save my Beech chisel mallet from being ruined. I have also invested in a really nice Wetterlings hatchet, which is hand forged and lovely.

A Hook Knife is still on the shopping list.... Spoons, Bowls and Kuksas here I come!... And, you dont need a bench!

More to come...

Sunday, March 2, 2014

The Story of a Country Kitchen

I hope you had a wonderful Easter weekend. Today Im sharing our kitchen makeover. As usual, I debated on whether or not to share this since in my mind our kitchen isnt quite finished. (I always refer to our house as a "work in progress".) But the fact is it probably will stay like this for a while, because when you have an old house that needs work, its all about priorities!

The reason I decided to share this is because we actually did this makeover on a budget of $1000. I always feel like paint is the most affordable way to completely make over a room and painting kitchen cabinets are a perfect example. The other ways to affect a remodel on a budget are to be resourceful, use existing elements if possible, prioritize those things you feel are worth the extra money and finally, do the work yourself!

BEFORE:

This is how the kitchen looked when we did a walk-through on the house. Can you believe that I lived with it like this for almost a year? But it was almost exactly a year ago (I was 6 months pregnant at the time) that we were ready to tackle the kitchen!

Believe it or not, we did the majority of the work one Saturday. My daughter spent her first night away from home with her grandma and we worked all day and some of the night. I did all of the painting while Justus took care of trim work, light fixtures, and other time consuming details.

I had never painted cabinets before (in our previous house we purchased new cabinets when remodeling our kitchen) and I was very nervous. But there was really no reason to replace these cabinets. Sure, they were ugly, but these cabinets were as solid as could be, made with thick oak wood.

I visited our local Benjamin Moore store and they helpfully pointed me in the right direction as far as what kind of primer to purchase and a cabinet paint roller. The $6 for the cabinet paint roller was worth every penny! (smile) I originally wanted to use an oil-based primer, but since I was pregnant at the time, we went with latex. I painted one coat of primer and three coats of paint.

AFTER:

I used the same color for the cabinets and walls (Simply White by Benjamin Moore). Since our kitchen is on the small side, I knew white would not only brighten the space, but also make it appear larger.

If youve read about our butcher block countertops, then you know they are something I have always wanted. The warmth of wood looks beautiful with an all white palette. These countertops are my favorite thing in our kitchen. They were made by my husband and father-in-law from 100-year-old reclaimed barn wood (you can read more about them here).

We were fortunate that the countertops were essentially free since my father-in-law had the wood and tools needed to build the countertops on hand. The countertops are an example of being resourceful though... sometimes unique and lovely things can come about when you have to think outside the box.

BEFORE:

BEFORE:

When we purchased our house, the original bead board was covered with foam tiles. Justus and I had no idea what the condition of the bead board would be in when he removed the tiles. He did the laundry room and kitchen at the same time and we were pleasantly surprised that although the bead board was covered in pealing old teal paint and had a few holes, it was in a salvageable condition. This was a very dirty project and Justus did it all himself since I was pregnant and we knew we were potentially dealing with lead-based paint. He shut off this section of the house for a day and wore a face mask when sanding and making repairs. He then added a coat of primer and a coat of paint before opening this section back up. I added three more coats of paint after that to ensure everything was sealed properly and would be for several more years.

AFTER:

AFTER:

By renovating the ceiling, we were able to raise the ceiling height by a good 4". This was a very positive thing since the back portion of our house originally was a porch (before there was such a thing as indoor plumbing) and has a lower ceiling height than the rest of the house. Justus added trim on top of the cabinets for a finished look.

The farmhouse sink is also original to the house and fortunately is in excellent condition. We did replace the faucet and spent about $200 on it I believe. I purchased the cabinet hardware off of Ebay for about 1/3 of the price of what we would have spent somewhere like Lowes. We also replaced the dishwasher.

The white bead board cabinet is something I found prior to purchasing our home and I use it for a pantry (you can read more about it here).

Later I purchased this wood piece at a local antiques store and I use it for extra storage since we have a limited number of cabinets. I love both pieces in the kitchen since I feel like they must have been made around the same time period as our house and the bead board gives a cohesive look.

BEFORE:

AFTER:

This view is looking into the laundry room and then a bathroom. Eventually well replace the floors in this portion of the house to match the rest of the downstairs. We left the walls as they were because the bead board behind didnt appear to be in good condition from what we could see and although this is a type of paneling, it is solid wood about 1/4" thick. And actually I feel like a little variation from bead board is okay... our entire house is bead board!

I found this farmhouse table for something like $40 and refinished it. We love this old table and even though were a little crowded, we usually eat our family meals here instead of the dining room.

Some day well replace the refrigerator and stove, but for now, these work fine.

Although our kitchen is by no means perfect, its cheerful, charming and the heart of our home. I dont feel like you have to spend a lot of money to bring about some major improvements. We have some ideas in mind for additional improvements, but with an old house, a budget, and limited time, you learn to prioritize home repair projects and be content until the time is right.

And although I do try to keep our kitchen clean and uncluttered, I have to be honest... I normally have a high chair with an occupant in one corner...

And my refrigerator is always packed with sweet artwork. (smile)

For fun, here is a list of what we purchased for our kitchen makeover with approximate prices:

- Paint $100

- Cabinet Roller $6

- Trim $75

- Faucet $200

- Cabinet Hardware $85

- Light fixtures and covers $150

- Dishwasher $400

Friday, February 21, 2014

The 4 Important Steps of How to Build a Chicken Coop

When you build a chicken coop, there are four main elements that you want to keep in mind. We will cover them in this article, and when youre finished you will be ready to move onto the next step, getting the plans and breaking out the power tools.

The first step we will cover is size. This has a direct effect on the number of birds you can hold and is often one of the first mistakes beginners make. After that you will be able to pick out the style that best suits your needs and the amount of space you have.

Once you have this information, you will want to look at building both a healthy and safe coop. More on that in a moment.

Lastly you will want to make sure that you build a nice looking hen house. But you may be surprised when you find out how important this step really is.

Some of you may already be itching to break out the power tools, so I will get started and show you how to build a chicken coop.

Step #1: Picking the Right Size

You may be thinking that this is an understood part of building a chicken coop. You know where you want to put the chicken coop and you know how many chickens you want, isnt that enough? The answer is no. Just because you have a spot picked out, that doesnt mean it is the most ideal. You may also run into trouble if your desired hen house doesnt match the number of chickens you plan to get.

Each chicken requires at least 3 square feet of room inside of the chicken coop. As you can see, this will directly influence how many chickens you can hold, and where you can build your coop.

As you can imagine, if the chicken coop becomes too crowded, your hens will spend the majority of their time fighting for room rather than laying eggs. Since this is the reason, most people build chicken coops, it will waste both the money and time youve invested. So now is the perfect time to decide how many chickens you plan to raise.

In the event that there is too much room in the coop later you always have the options to add another hen or two.

Step #2: Choosing the Right Type of Chicken Coop

As you already might know, there are two types of chicken coops. The first is portable, and is often referred to as a chicken tractor. The other is fixed and is usually built to hold more chickens. Lets look at the two types and you can get a better idea of what best suits your needs.

First well look at the portable ones. There are several benefits to building a portable chicken coop, besides being portable they are easier to maintain. Since you can move the coop around, maintenance is much easier. Instead of bringing the tools to the coop, you can bring the coop to your tools. Cleaning the coop is also easier with portable hen houses.

But there is a downside, and we need to cover that as well. If you build a portable chicken coop, dont expect it to last for a long time. Portable chicken coops are not nearly as stable as their fixed counterpart.

Fixed or static hen houses are much more stable than the portable ones, and a well built coop can last for many years. Of course you need to plan the location for your coop very carefully. Once it is finished, moving it will be a very time consuming process.

Here are some things to consider when you build a static roost. First, chickens need a lot of sunlight. Make sure to build the chicken coop so that it gets as much sun as it can each day. But you will also want provide your coop with protection from the other elements. Strong rain or wind can be a problem, thats why it is a good idea to build your coop under a group of trees or next to a larger building.

Another thing to keep in mind when you build a fixed hen house is that it shouldnt be built on low ground. Make sure to build it on the a higher part of your yard. If you get strong storms, your chicken coop could become flooded. If this happens, you learn what the expression "madder than a wet hen" means.

Step #3: Keeping Your Coop Safe

One of the most important aspects of learning how to build a chicken coop is keeping your birds safe.

There are many different types of predators that will prey upon your hens if you arent careful. This can be anything from the neighborhood cats and dogs to less likely threats such as rats. If you live in the country, you may also be at risk of attracting larger predators.

These can include foxes, coyotes and badgers. You will want to assure that you use strong enough fencing to keep the more determined wild animals out. Make sure to bury your fence deep enough in the ground to keep out animals that try to dig their way into the coop.

Dont forget the threat from above. Hawks will also prey upon chickens, so it might be necessary to cover your chickens run with a roof or fencing.

Step #4: Keeping Up Appearances

Learning how to build a chicken coop can be a really fun experience which also makes a great family project.

A well built chicken coop should be both healthy and comfortable for your chickens but also look nice. Nobody likes an eyesore, and if you dont take the time to finish out your coop, you might get complaints rather than compliments from your neighbors.

This would be a shame, since a chicken coop can add a unique element to your yards landscaping. One that will have your neighbors talking for all of the right reason, and your family supplied with fresh eggs every morning for breakfast.

If you build your chicken coop in the city, you will want to check your city ordinances for any that regulate if and how you can build your coop.

Read More Chicken Coop Plans Here

Monday, February 10, 2014

Speaking of Wood

Some thoughts from the Unplugged Woodshop….

; )

Happy New Year !

Tuesday, February 4, 2014

The basics of cabinet making Part 2

The 4 taller cabinets are to have 3 adjustable shelves each. I want to make the holes for the pegs now, before the cabinets get assembled. Im using my simple pegboard jig to guide for the holes, and am using 1/4" drill bit to make them. Note: there are two different sizes of shelf pins - I like the bigger ones for more stability.

I also will do all the sanding at this point. These things are much easier to do before everything is put together.

Ive now started assembly. With all the pieces cut, its just a matter of putting it all together. I install the supports (1x3 plywood slats), and the sub-toe kick (also plywood) as shown in this picture. The front toe kick will be 1/4" oak, stained to match the cabinets, and will be applied over top of the sub-toe kick.

Next, I install the back panel. This is just 1/4" luan material, since it will be pretty much unseen. This panel will help keep the unit square, until it is installed. Note: Square up your cabinet as soon as you can, before this panel goes on!

Ive gotten two of the taller cabinets assembled. Two more to go, and then I will make two smaller cabinets to go with this set. Once this casework is done, I will move on to face frames and doors.

Bear approves of the new cabinets...

a couple of restaurant tables

well, heres a fun project ... two large english elm slab tables with metal rebar bases for a restaurant in bethesda, maryland. weve been working with amy krol, a competent and responsive designer at aria group architects in oak park, illinois. her concept sketches are above and we have gone back and forth with her over the last two months, refining the construction and material selection details. were on the home stretch now and aside from a column location question (the column hasnt been built yet) were ready to wrap them up and ship them out. click the photos to enlarge them ...

well, heres a fun project ... two large english elm slab tables with metal rebar bases for a restaurant in bethesda, maryland. weve been working with amy krol, a competent and responsive designer at aria group architects in oak park, illinois. her concept sketches are above and we have gone back and forth with her over the last two months, refining the construction and material selection details. were on the home stretch now and aside from a column location question (the column hasnt been built yet) were ready to wrap them up and ship them out. click the photos to enlarge them ... we started at berkshire products in sheffield, massachusetts, a great source of amazing and unusual wood for woodworkers the world over. we picked these three slabs from their photos on the internet. the one above for the single long table ...

we started at berkshire products in sheffield, massachusetts, a great source of amazing and unusual wood for woodworkers the world over. we picked these three slabs from their photos on the internet. the one above for the single long table ... and this matchinig pair, which will be butted end to end and notched around the column as shown in the drawings below.

and this matchinig pair, which will be butted end to end and notched around the column as shown in the drawings below. next came the model stage. i drew them in my cad program, but in the end, the random, this looks good placement was the way to go ... some things you can overplan.

next came the model stage. i drew them in my cad program, but in the end, the random, this looks good placement was the way to go ... some things you can overplan. there was some concern that the skinny rebar (actually, its 5/8ths and not that skinny) would flex, as in theory, rebar gets its strength from the concrete surrounding it ...

there was some concern that the skinny rebar (actually, its 5/8ths and not that skinny) would flex, as in theory, rebar gets its strength from the concrete surrounding it ... sam said it would be no problem but just for fun, we loaded the unglued model and applied a little side pressure ... solid as a rock, even with 1.8th inch rubberwood dowels and no glue ...

sam said it would be no problem but just for fun, we loaded the unglued model and applied a little side pressure ... solid as a rock, even with 1.8th inch rubberwood dowels and no glue ... we trimmed, smoothed and stiffened the single slab ...

we trimmed, smoothed and stiffened the single slab ... cool top ... and started construction on the real bases in the metal shop.

cool top ... and started construction on the real bases in the metal shop. sam came up with the great concept of temporary pipe and threaded rod through the corner holes where the table bases will be bolted to the floor and to the wood tops, which held the two 1/2 x 12 steel plates parallel, and, when the bolts were tightened, completely square. he tacked the rebars randomly and checked them out, then welded them securely ... very cool, but when we figured it out, the long base weighs +/- 450 pounds !! fortunately, we were prepared and actually constructed all the steel bases on dollies.

sam came up with the great concept of temporary pipe and threaded rod through the corner holes where the table bases will be bolted to the floor and to the wood tops, which held the two 1/2 x 12 steel plates parallel, and, when the bolts were tightened, completely square. he tacked the rebars randomly and checked them out, then welded them securely ... very cool, but when we figured it out, the long base weighs +/- 450 pounds !! fortunately, we were prepared and actually constructed all the steel bases on dollies. base #1, resting in the driveway ... this dolly was a touch under built...

base #1, resting in the driveway ... this dolly was a touch under built... the double table is wider at +/- 42" and we built those bases upside down, using 1/4 x 20" steel plates for the base tops to give the wider wood tops more support.

the double table is wider at +/- 42" and we built those bases upside down, using 1/4 x 20" steel plates for the base tops to give the wider wood tops more support. we bolted them to some timberstrand on the floor of the garage ...

we bolted them to some timberstrand on the floor of the garage ... and built a two piece mock column the appropriate size for the full effect.

and built a two piece mock column the appropriate size for the full effect. view down the 17 footer

view down the 17 footer the column top is shown here moved off center to its approximate location. the final column location will be determined with cardboard templates by the job foreman on site and we will cut them to the templates before shipping ...

the column top is shown here moved off center to its approximate location. the final column location will be determined with cardboard templates by the job foreman on site and we will cut them to the templates before shipping ... the single slab table ... 98" x +/- 30"

the single slab table ... 98" x +/- 30"loyal readers will note our upgraded garage extended workplace we thought we were done up here after the big tables last year, but noooo ... so, now we have a painted floor, full insulation and sheetrock, heat if we need it, and today, a commercial dehumidifier arrived for summer work ... were officially ready for the big ones ...

Saturday, January 25, 2014

The Secrets of the Leg Vise Revealed!!

Enjoy...

If you watch very closely at the 0:11 to approximately 00:13 second mark, you may just see for yourself the secrets finally revealed of the traditional leg vise. So, this is what the experts were talking about, in all of the fancy magazines all of this time!

Seriously though...Imagine working wood in this way; relaxed, focused and at perfect ease with the wood, the tool and the joinery. Incredible...

We all can learn something from this, regardless of the work you do.

Cheers!

Read More..

If you watch very closely at the 0:11 to approximately 00:13 second mark, you may just see for yourself the secrets finally revealed of the traditional leg vise. So, this is what the experts were talking about, in all of the fancy magazines all of this time!

Seriously though...Imagine working wood in this way; relaxed, focused and at perfect ease with the wood, the tool and the joinery. Incredible...

We all can learn something from this, regardless of the work you do.

Cheers!

Thursday, January 23, 2014

Here are a couple of pretty cool turning videos

Im not sure how I found these videos but they are pretty cool and pretty old (for YouTube). I really like the tool rest he has in the bowl video.

Read More..

Subscribe to:

Posts (Atom)